Sedex-audited jewelry factory in China: 16 years of Sedex audit; Raw materials and finished jewelry comply with CA Prop 65 (California Proposition 65) and REACH.

16-year custom jewelry manufacturer: OEM/ODM for stainless steel, brass, titanium jewelry; design support, sampling, bulk production.

U.S. office communication: Local U.S. customer service, supported by China factory production capacity and global shipping.

OEM/ODM Custom Fashion Jewelry & Accessories Manufacturer

Get Your Best Quotation

About Haosen Jewelry | A Fashion Jewelry Factory from China

We are Haosen Custom Fashion Jewelry Factory, established in 2008, a Chinese custom fashion jewelry manufacturer for OEM/ODM jewelry and accessories.

Our factory is Sedex-audited with 16 years of Sedex audit reports and SGS-certified. Raw materials and finished jewelry comply with CA Prop 65 (California Proposition 65) and REACH requirements.

We manufacture custom jewelry using 316L stainless steel, brass, alloy, titanium, pearls, rhinestones, zircon, resin, and leather. Products include fashion rings, necklaces, bracelets, pendants, anklets, body piercings, custom lapel pins, cufflinks, and tie clips.

We support custom design, mold development, sampling, and bulk production for custom jewelry brands, clothing brands, wholesalers, and retailers, with worldwide supply.

Why Choose Us

16-year SEDEX-Audited Jewelry Manufacturer

Haosen maintains a 16-year SEDEX (SMETA) audit track record (2009–2025) and holds SGS Verified Alibaba Gold Supplier certification. We specialize in manufacturing fashion jewelry, accessories, and metal gifts. using 316L surgical-grade steel, eco-friendly brass, leather, resin, and so on. Every material and products batch undergoes compliance testing to meet EU REACH and California Proposition 65 standards.

OEM Fashion Jewelry Supplier: 24-Hour Support & U.S. Showroom

As a Fashion Jewelry OEM supplier, we maintain a 24-hour response protocol for all technical and production inquiries. Our operations including sales,service, Quality Control (QC), and Production teams, ensure rapid response times and expert resolution of client requirements. Our U.S.-based team and Showroom in Chula Vista, CA, San Diego County, serve for real-time consultations and in-person sample verification.

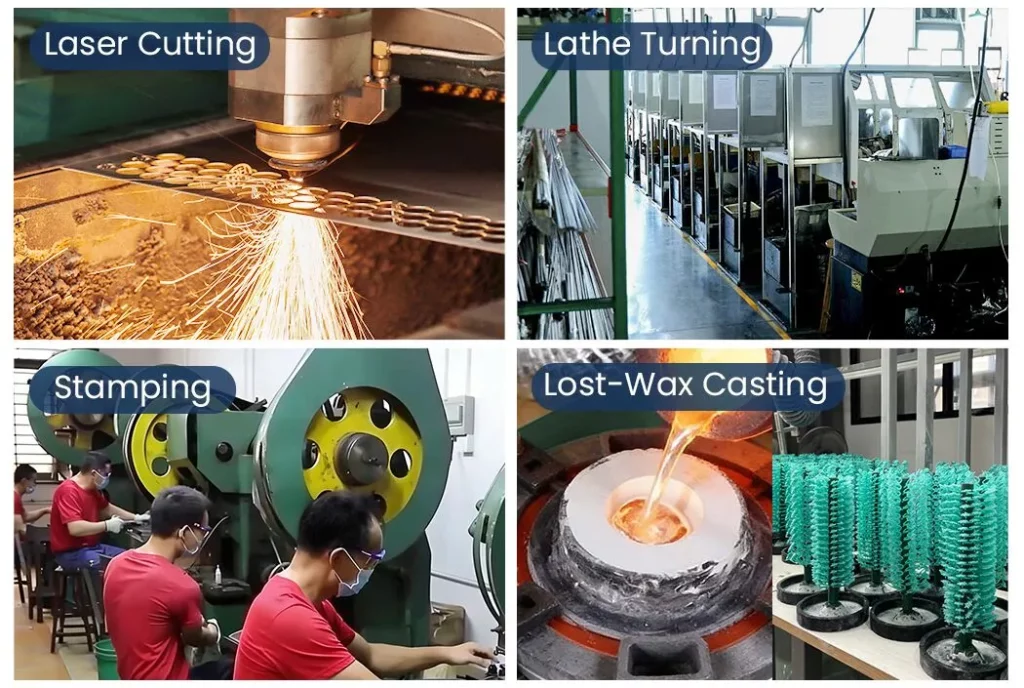

Vertically Integrated Production

Haosen integrates multiple forming processes to support different structures, designs, and cost requirements, including stamping for efficient production, laser cutting for clean and accurate shapes, lost wax casting for detailed 3D designs (through a long-term partner foundry in which we hold an equity stake), and lathe machining for tight-tolerance components. This allows us to optimize the right manufacturing route for each product, reduce dependency on outsourcing, and ensure consistent quality and lead time from prototype development to scale-up production.

Surface Finishing Solutions

Haosen provides end-to-end surface finishing options to meet different style demands and durability standards, including enamel for vibrant color effects, PVD plating for premium wear resistance, and electroplating for stable and cost-effective finishes. With controlled process parameters and strict QC inspection, we minimize common issues such as uneven coating, weak adhesion, and color variation across batches—helping your products maintain a high-end appearance and consistent quality in mass production.

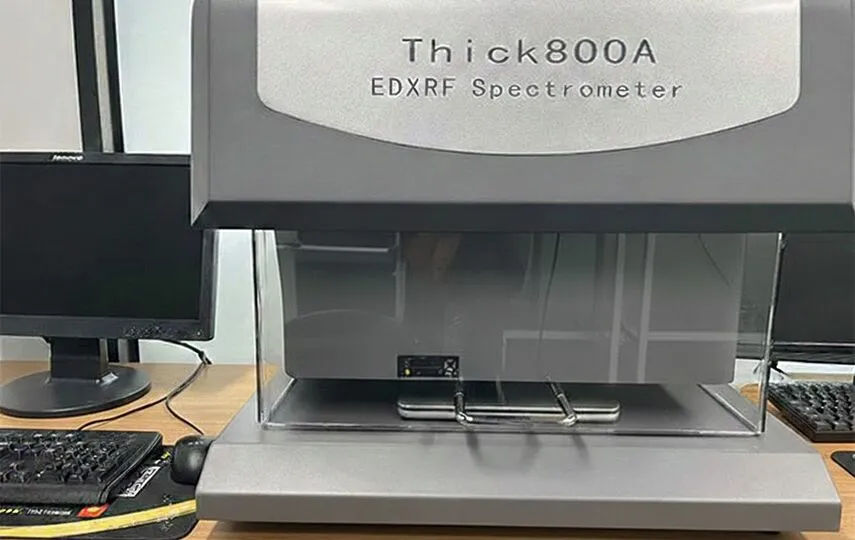

Metal Material & Plating Analysis

Our jewelry factory utilizes professional EDXRF Spectrometers (Thick800A) for non-destructive material analysis on every batch. We precisely monitor PVD plating thickness to guarantee superior wear resistance and finish longevity. This rigorous screening ensures Lead (Pb), Cadmium (Cd), and Nickel (Ni) levels are 100% compliant with REACH and California Proposition 65 standards.

Salt Spray Test

We perform jewelry’s 48-hour accelerated testing in a Salt Spray Chamber. This deep-level oxidation test verifies the durability of our jewelry finishes, ensuring maintains its original metallic luster even under harsh coastal conditions.

Constant Temperature Test

Simulates extreme global climates to verify physical stability. This quality check prevents fading, rusting, or structural damage caused by temperature fluctuations, providing consistent reliability for international markets.

Logistics Reliability Test

We use specialized Vibration Testers to replicate the rigors of global shipping. Our protocol simulates vehicle speeds of 25~40km/h with a precise vibration frequency of 100-300rpm, ensuring the structural integrity of both the jewelry and its packaging. This high-intensity simulation guarantees that Haosen orders withstand long-haul transit and arrive in pristine condition.

Haosen Quality Testing

Custom Made Fahion Jewelry

Stainless Steel Jewelry

Stainless steel jewelry is resistant to corrosion, rust and tarnish, ensuring the jewelry remains in pristine condition

Brass Jewelry

Haosen brass jewelry pieces are treated to be hypoallergenic, made with eco-friendly materials for sustainable fashion.

Zinc Alloy Jewelry

Zinc alloy jewelry production cost is relatively low, and jewelry products with affordable prices can be produced.

Titanium Body Jewelry

Titanium jewelry is particularly suitable as piercing jewelry (such as nose rings, belly button rings, etc). Design your own body jewelry now.

Contact Us

Phone / Whatsapp / Wechat

China Factory Address

Room 101, No. 2 Zhen Rong Road, Wu Sha, Chang An Town, Dong Guan City, Guang Dong Province, China 523859

U.S. Office Info

Tel: +1 619-358-0328

Email: [email protected]

Address: 3802 Main Street Suite 3

Chula Vista CA 91911